Venda quente 1.8 m wer ep1802t impressora de tecido de impressora de bandeira direta

Especificações

Usage:Direct flag printer

Plate Type:1.8m sublimation printer

Tipo: Impressora Jato de Tinta

Condição: Nova

Grau automático: automático

Voltage:AC 220V 50/60HZ

Dimensions(L*W*H):3.36x1.1x1.58m

Weight:830KG

Warranty:1 Year, 1 year

Print Dimension:1.8m width

Ink Type:Waterbased ink

printhead:5113/DX5

ink type:waterbased ink

printing width:1.8 meter

cor: CMYK

Materail type:polyester

RIP software:for free

after sales service:supplied

Parâmetros técnicos

| Tecnologia de Impressão | Drop-On-Demand Piezo electric Technology | |||

| Number of print-heads | 2 pcs Epson 5113.DX5 | |||

| Bicos | 4* 4 color ( C M Y K ) | |||

| Tipo de tinta | textile printing ink | |||

| Ink supplying system | Auto sense ink supplying system | |||

| Intelligent monitoring system | auto detecting system while lacking ink | |||

| Heating & drying | Heating system | Equipado | ||

| Heating temperature | available: Normal temperature-25°C suggest temperature: 30°C ----40°C | |||

| Sistema de secagem | Equipado | |||

| Media accetpable | Roll Fabric, textile | |||

| Print width max | 1800MM | |||

| Rapidez | Mass production mode | 30.0m2/h | ||

| Quality mode | 22.0m2/h | |||

| Ultra quality mode | 15.0m2/h | |||

| Print-head cleaning system | Automatic cleaning & auto capping system | |||

| Interface | USB2.0 | |||

| Software RIP | Maintop or Photoprint | |||

| Power supply | AC220V/110V 50/60Hz | |||

| Ambiente de trabalho | Temperature: 20℃~32℃; Humidity: 40%~60% | |||

Visiting Customers

Excelentes serviços pós-venda

Garantia de 1.One ano

You can discuss operation and maintenance with our technician online support service by Skype, MSN etc. Remote control will

be provided upon request.

2. Livre troca de novos componentes

Our quality is guaranteed 100%, the spare parts can be replaced within one year free of charge includes the airfreight by express,

except for the print head and some consumable parts.

3. Consulta online grátis

The technician will keep online. No matter what kind of technical questions that you may have, you would get a satisfactory

answer from our professional technician easily.

4. Instalação e treinamento gratuitos no local

If you are able to help us with getting the visa and also would like to bear the costs involved like flight tickets, food, etc, we can

send our technician to your office, and to give you a free installation and training for as long as you know how to operate it

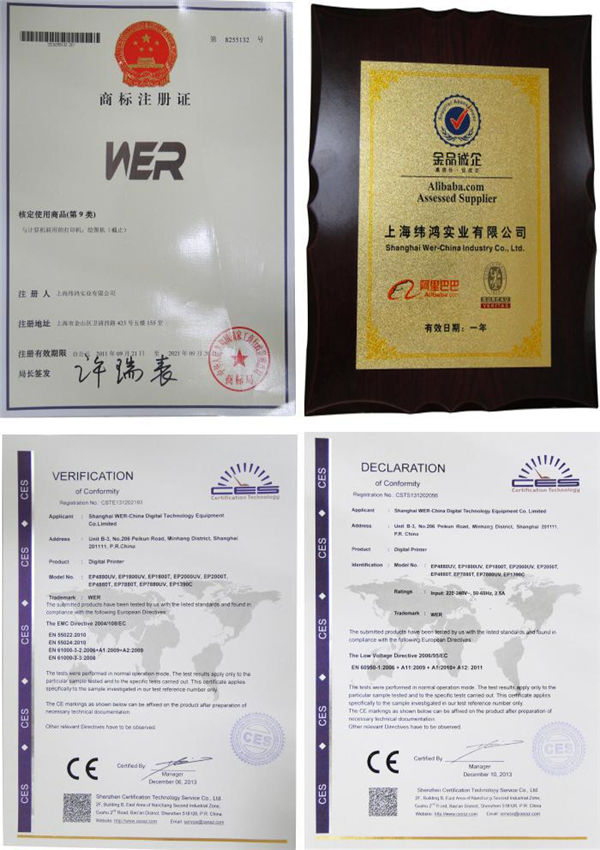

Por que escolher o WER

A wide range of great products totalling over 50000 in future

. WER means customers can, employees can and investors can

. Professional customer after services and troubleshooting

. Become our potential partners as long as you believe yourself

. Friendly helpful customer services from WER.com

. Free or low shipping cost from China to any countries

. No minimum order quantity request

. PayPal, Credit Card And Boleto payment options

. Dropshipping is direct from us to users

. Shipping protected with product declaration

Perguntas frequentes

The sublimation and drying machine.

The main applications of sublimation and drying machine.

As the costs of sublimation inks and directly printing textiles cheaper and cheaper, the sublimation drying machine becomes more and more popular for printing display media, flex banner, textile belt, home textile items and so on.

What is the difference of sublimation drying machine and direct printing machine+ color developing machine?

The advantages of sublimation drying machine: easy to operate, drying as soon as printed, more popular for small printing business.

The advantages of direct printing machine+ color developing machine: Developing colors faster with lower power, better printing quality, longer life time, suitable for industrial printing business.

What should the customer notice before starting the printer?

a. Please make sure that the USB line and power line connect well.

b. Please check whether the ink is enough in the ink tanks. The ink tanks should be about 80% full.

c. Please check if there is air in the ink tubes, whether print head is clogged. If the head is clogged, the customer should use the cleaning solution to clean the head.

d. Make sure that the cleaning head ways is correct to protect the other parts.

e. please check if the printing platform is plain. If not plain, the customer can adjust the screw at bottom of the leveling measurement.

f. before printing, the customer should test the print nozzles. If there is missing some lines, please choose automatic head cleaning or manual cleaning the head.

g. please check the strength of the light of UV lamp, to make sure the UV lamp works well.

Notices when to turn it off?

Before shutdown, users should check and confirm whether the sublimation drying machine in normal standby mode or not.

If the the ink lacking lamp flashes,Please change the ink cartridge in time.The sublimation ink drying machine should have been turned off when all the printing works finished.

Thermal sublimation drying should be turned off in the form of cube power key.Do not shut down in the form of directly cut off the power,or it will cause serious consequences.

After shutdown, the sublimation drying machine should be covered by cloth cover ,in order to prevent dust intrusion damage from heating sublimation plate.